Chain link fence, also known as guardrail, is a metal mesh structure commonly used in walls, fences, flower beds and other places. It is

Chain link fence, also known as guardrail, is a metal mesh structure commonly used in walls, fences, flower beds and other places. It is

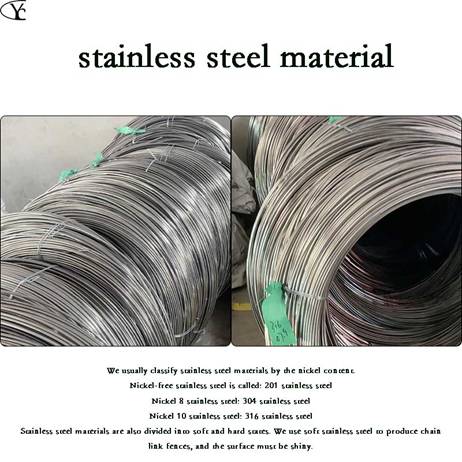

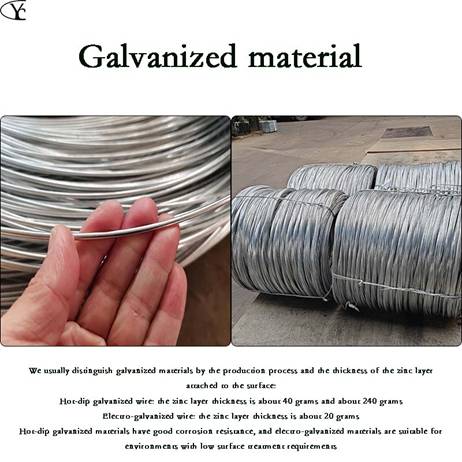

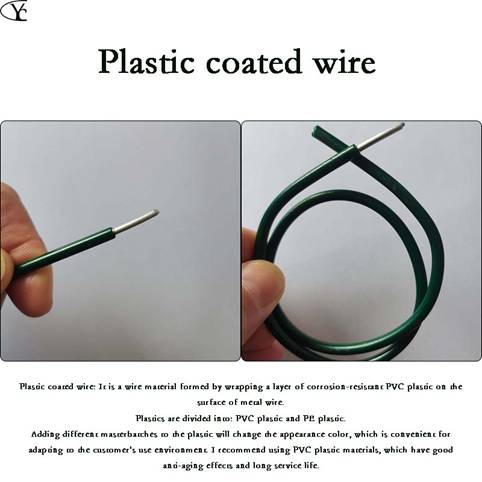

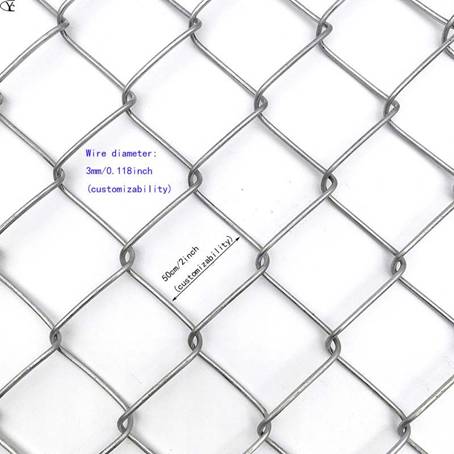

All specifications of the above materials, the thickness of the wire diameter, and the hardness of the materials will affect the production of the wire mesh.

Network port size:

The measurement method of the network port size is to determine the size by measuring the parallel line of the network port. The minimum size of the network port we can customize is about 10 mm, and the maximum size we can customize is about 150 mm. The minimum wire diameter can be customized to 1 mm, and the maximum can be customized to 5 mm. The production mainly depends on the customer's requirements.

Simple classification of chain link fence:

>

>

The edge processing methods of chain link fence are generally divided into bending and twisting, both of which prevent the wire mesh from detaching, and each has its own advantages.

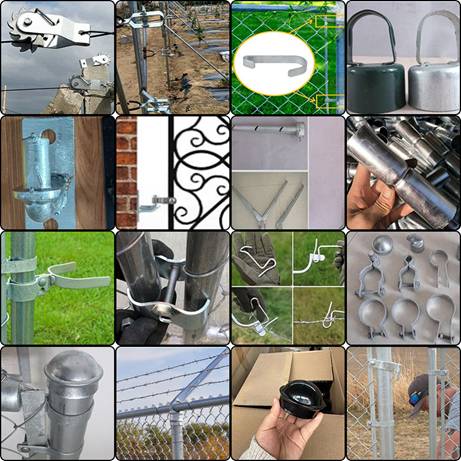

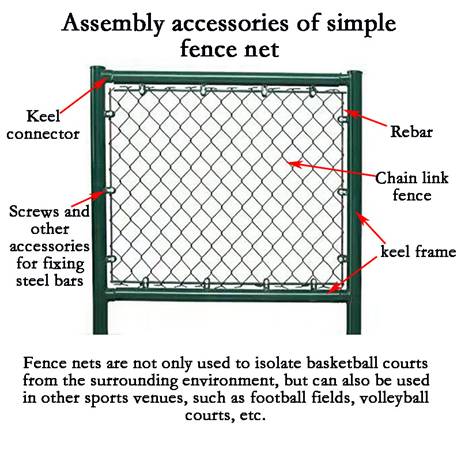

Chain link fence accessories assembly and samples:

We have many kinds of accessories that can be assembled into this kind of fence net

The assembled protective net is both beautiful and well protected.

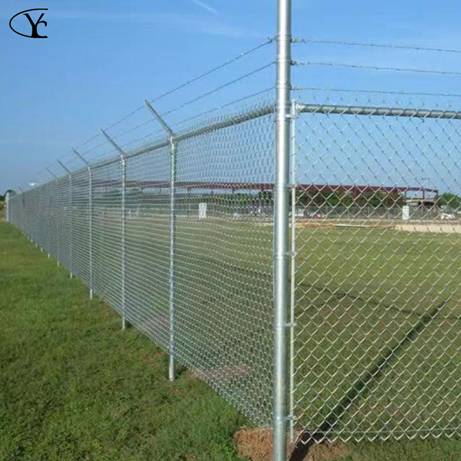

The installation method of hot-dip galvanized chain link fence usually includes the following steps:

Determine the layout and size of the fence, and prepare the required materials and tools, including chain link fence, posts, beams, connectors, screws, nuts, bolts, screwdrivers, wrenches, levels, etc.

Determine the position of the column:

Determine where the posts will be located where the fence needs to be installed, and use rulers and measuring tools to ensure the locations are accurate.

Digging holes to install columns:

Use a shovel or excavator to dig a foundation hole of appropriate depth at the position of the column. The depth is generally required to be 50-80 cm.

Place the column into the foundation hole, use a level to adjust the verticality and level of the column, and use supports (such as wooden blocks) to fix the position of the column.

Connect beams and columns:

To connect the beams to the columns, you can use connectors, screws, nuts or bolts, and fix the connection between the beams and the columns according to the design requirements.

Install chain link fence:

Spread the hot-dip galvanized chain link fence along one side of the beam and tighten it, and use U-shaped buckles or other connectors to fix the chain link fence to the beam.

If there are multiple layers of chain link fence that need to be stacked, make sure the connections between the layers are firm and you can use bolts and nuts to connect them.

Top fixation:

At the top of the chain link fence, use top buckles or other fixings to fix the chain link fence to the posts to ensure the stability and safety of the chain link fence.

Check and clean:

Check that all connections are tight to ensure that the fence structure is solid and reliable.

Clean up the construction site, remove debris and garbage, and keep the surrounding environment tidy.

The above are the general installation methods of hot-dip galvanized chain link fence. The specific installation process needs to be adjusted according to the actual situation and design requirements. During the installation process, please be sure to pay attention to construction safety to avoid accidents

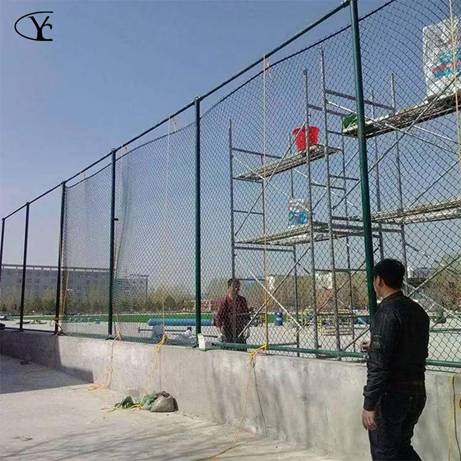

Assembly accessories and finished products of plastic coated chain link fence:

To install this relatively tall stadium net fence, you need to spread the net first and fix one side of the keel by lifting flat bars.

The fence net structure is stable and firm and can withstand a certain amount of impact and extrusion force.

The mesh size and wire diameter of the fence net are scientific and reasonable, which can prevent basketballs from passing through the mesh and causing safety hazards, and will not affect the normal progress of basketball.

The fence net can also be surface sprayed to adapt to different usage scenarios and environmental requirements and increase its aesthetics.

The 4-meter-high basketball court fence net uses high-strength hot-dip galvanized chain link fence material, which has the characteristics of corrosion resistance, wear resistance, and high tensile strength, making the entire fence net structure stable and firm and able to withstand a certain amount of impact and extrusion force.

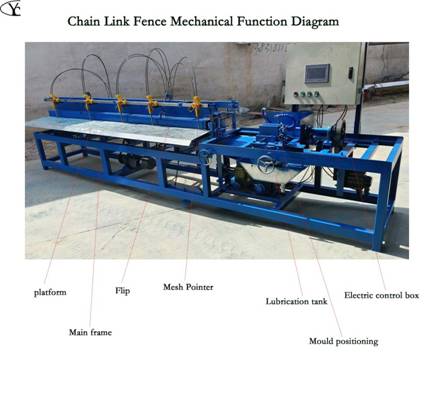

About Chain Link Fence Machinery:

Main function: Rotate the raw materials into shape, connect and weave to form a mesh structure

Edge locking machine:

Main function: lock the edge of the screen to shape, divided into two ways: twisting and bending (the picture shows the twisting structure)

Shrinking machinery:

Shrinking machine: The main function is to shrink the wire mesh, save space, facilitate transportation and reduce freight costs.

Simple specification classification:

| name | pattern | Width (width of the web that can be produced) | Motor | Function | Remark |

| Molding machinery |  | 2m | Power: 1 three-phase 3.8 kW servo motor Cut off: 1 three-phase 0.75 kW ordinary motor Flip: 1 three-phase 1.5 kW ordinary motor | Forming and weaving raw materials into nets | Width accumulates downwards: 6 meters can produce nets of all widths, which is inefficient and costly. |

| 2.5m | |||||

| 3m | |||||

| 4m | |||||

| 6m | |||||

| Edge locking machine |  | 2m | Three-phase 0.75 kW ordinary motor * 4 sets | Edge locking treatment | Divided into two structures: bending edge and twisting edge |

| 2.5m | |||||

| 3m | |||||

| 4m | |||||

| 6m | |||||

| Rewinding machinery |  | 2m | Three-phase 0.75 kW ordinary motor*1 set | Reduce the size of the screen Reduce volume and facilitate transportation | |

| 2.5m | |||||

| 3m | |||||

| 4m | |||||

| 6m | |||||

| Wire mesh production machinery can be modified according to the special requirements of customers to meet their usage requirements. | |||||